When selecting CO2 cartridges for your business—whether for beverage dispensing, outdoor sports, or industrial use—the material of the cartridge plays a crucial role. The two most common options in the market are aluminum and stainless steel, each offering distinct performance characteristics.

This guide breaks down the key differences, use-case considerations, and how to decide which material better suits your operational needs.

Stainless vs Aluminum CO2 Cartridges at a Glance

| Feature | Aluminum | Stainless Steel |

|---|---|---|

| Weight | Lighter | Heavier |

| Corrosion Resistance | Good | Excellent |

| Strength | Moderate | High |

| Pressure Tolerance | Up to ~900 psi | Up to ~1800 psi |

| Cost | Lower | Higher |

| Typical Applications | Soda, bikes, whipped cream | Airguns, life vests, defense |

| Reusable? | Generally not | Often yes (if designed for it) |

When Aluminum Cartridges Make Sense

Aluminum CO2 cartridges are widely used in low-pressure or consumer applications. Their lightweight and cost-effective nature makes them ideal for:

- Bike tire inflators

- Carbonated drink makers

- Cream whippers

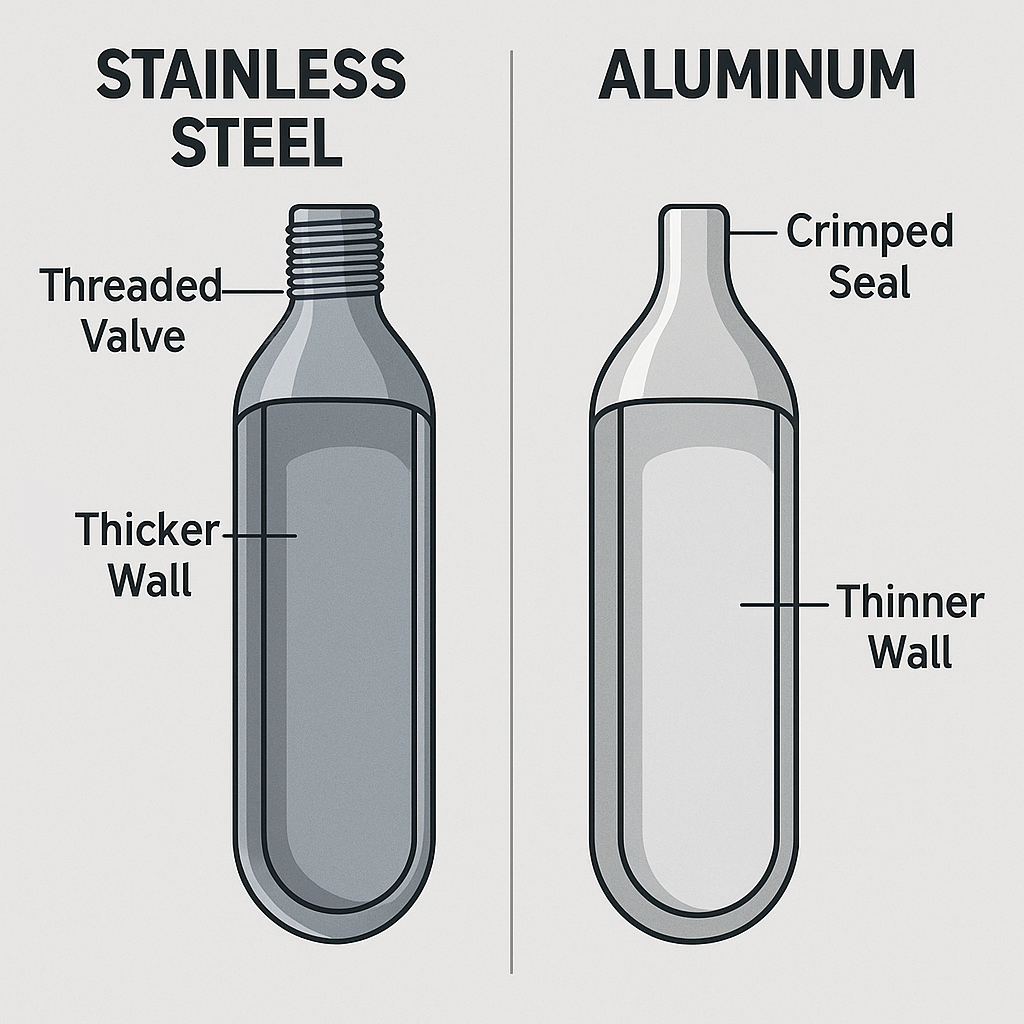

Because aluminum is easier to machine and resists rust, it’s commonly chosen for single-use cartridges. However, these cartridges typically lack threading or pressure-rated valves, which means they are not intended for refilling and should be safely disposed of after use.

Additionally, manufacturers often select aluminum when optimizing for shipping weight and production cost—both of which are discussed in detail in our CO2 cartridge specifications and logistics guide.

Why Stainless Steel Is Used in High-Performance Applications

Stainless steel, while heavier and more expensive, brings superior mechanical strength and long-term durability. It is particularly well-suited to environments where:

- Higher internal pressure is required (e.g., 1200+ psi)

- Exposure to moisture or chemicals demands maximum corrosion resistance

- Repeated use or refilling is expected

This is why stainless cartridges are commonly used in airsoft guns, life-saving equipment, and industrial-grade CO2 systems.

In fact, the engineering behind these containers must follow strict international standards for pressure vessels. These guidelines—covering aspects such as burst pressure, wall thickness, and safety testing—are well-documented in professional references like the Gas Cylinder entry on Wikipedia.

Which One Should You Choose?

Your decision should be based on both technical and commercial factors:

| Consideration | Go with Aluminum if… | Choose Stainless if… |

|---|---|---|

| Weight | Portability is key | Stationary or gear-mounted use |

| Usage Type | One-time use | Refillable or regulated |

| Cost Sensitivity | Budget is a top concern | Performance matters more |

| Pressure Needs | ≤900 psi is sufficient | ≥1200 psi is required |

| End-User Expectations | Consumer-grade | Military/industrial-grade |

If you’re supplying products to retail chains, aluminum may keep margins high and costs low. On the other hand, stainless is better suited for long-lifecycle use, reusable systems, or environments with strict safety codes.

Final Thoughts

There’s no universal answer—the best material depends entirely on your application. By understanding the technical trade-offs and lifecycle implications of aluminum vs stainless steel CO2 cartridges, you can make informed decisions that align with your buyers’ expectations and market needs.