The wrong CO2 cartridge decision often looks harmless at the beginning. Unit costs seem manageable, supply feels stable, and the system works well enough. The real problems usually appear later, when volume grows and small compromises turn into long-term constraints.

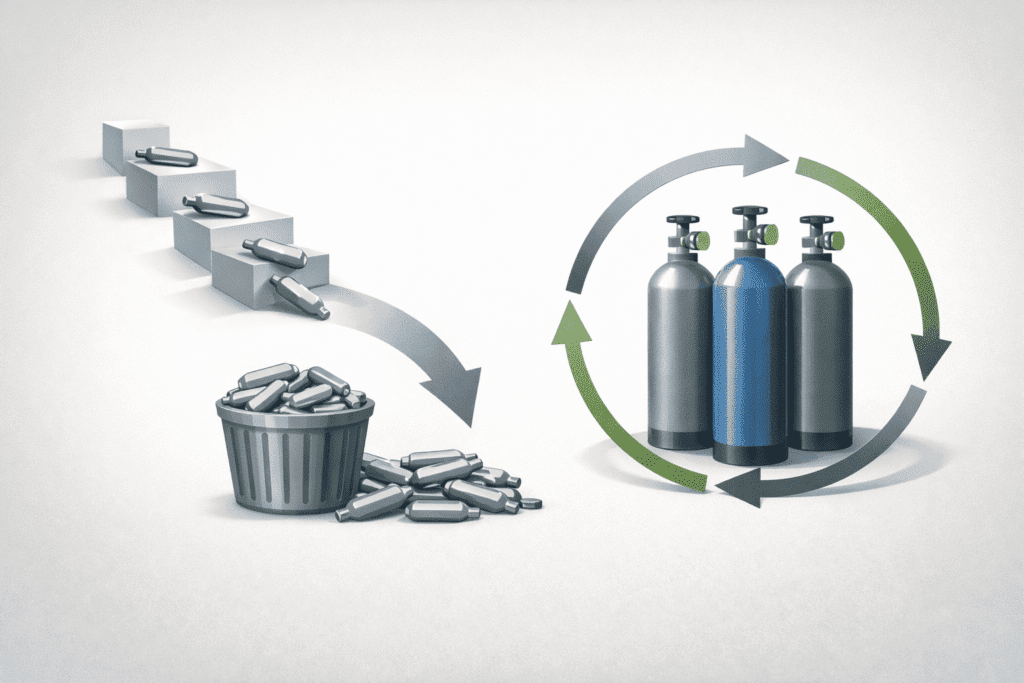

More brands are rethinking refillable versus disposable CO2 cartridges because growth exposes limits that convenience once covered up. From my position on the manufacturing side, this shift is no longer theoretical. It is already shaping how brands plan their next phase.

For a long time, disposable cartridges were simply the default choice. They were easy to source, easy to explain, and required very little operational planning. But as brands expand into more regions and applications, those early assumptions no longer hold.

Why did disposable CO2 cartridges become the default choice?

Disposable cartridges solved early-stage problems efficiently. Brands needed speed, simplicity, and minimal friction when launching products.

Disposable CO2 cartridges became popular because they reduced decision pressure at the start. There was no recovery loop to design, no refill process to manage, and no need to think deeply about long-term circulation.

In practice, disposable cartridges helped brands:

- Launch products faster

- Avoid return or refill logistics

- Rely on common market standards

- Keep early operations simple

This logic works when volumes are small and markets are limited. Many brands stayed with disposable cartridges simply because the system continued to function without obvious pain.

The issue is not that disposable cartridges are wrong. The issue is that the business environment eventually changes, while the system often does not.

What changed that is pushing brands to rethink this choice now?

Scale is the trigger, but it is not the only factor.

Brands are rethinking their CO2 cartridge strategy because cost, compliance, and supply stability are now connected. When one area becomes unstable, the others follow.

From what I see across different buyers, three pressures consistently appear.

Cost behavior shifts with volume

As volume increases, disposable cartridges bring more than unit cost. Packaging, freight, storage, and waste handling all grow alongside sales. Refillable systems require more planning upfront, but long-term cost behavior is easier to control.

Regulatory pressure increases

Environmental policies, pressure vessel transport rules, and waste regulations are becoming stricter in many markets. Disposable formats attract more scrutiny as shipment volumes rise.

Supply chain risk becomes visible

Disposable cartridges depend on constant replenishment. Any disruption creates immediate shortages. Refillable systems, when designed correctly, give brands more flexibility and buffering.

At this stage, brands stop comparing products and start comparing systems.

How do refillable CO2 systems change long-term economics?

This is usually where the mindset shifts.

Refillable CO2 systems move brands from repeated purchasing to managed circulation. Instead of paying again for single-use containers, brands invest in assets that move through a controlled loop.

In real projects, I consistently see four outcomes.

Clearer cost visibility

Refillable systems turn CO2 into a defined operating cost rather than a recurring packaging expense.

More flexible inventory planning

Brands rely less on constant inbound shipments, which matters for cross-border distribution and seasonal demand.

Stronger positioning with partners

More distributors and downstream customers now ask about waste reduction and long-term compliance. Refillable systems support those conversations naturally.

More stable technical standards

Refillable systems usually come with clearer definitions around cylinder size, working pressure, valve structure, and inspection cycles. That consistency reduces downstream issues.

How should brands evaluate refillable vs disposable today?

This is where many discussions go wrong. Brands often frame this as a preference question, when it is actually an execution question.

The real decision is not refillable versus disposable. It is whether the cartridge system matches the brand’s current and future operating model.

When brands evaluate this properly, the conversation usually moves through three stages.

First: clarify the growth path

Brands need to look beyond current orders and define what the next 12 to 24 months may look like. Volume, market expansion, and application range all matter. A system that works at low volume may become inefficient or risky at scale.

Second: assess operational capability

Refillable systems require different capabilities than disposable ones. Brands need to understand who manages circulation, how returns or refills are handled, and how quality is monitored over multiple cycles. This is not about complexity, but about readiness.

Third: translate strategy into hardware

Once brands reach this point, refillable stops being an abstract idea. It becomes a concrete system defined by cylinder size, working pressure, valve configuration, and how the refill loop integrates with existing distribution and service networks.

This is where many teams find it useful to move from discussion to inspection. Looking at real refillable cylinder configurations helps decision-makers understand what a refillable program actually looks like in practice, rather than debating the concept in isolation.

At the same time, practical handling and storage considerations become more important, especially for brands managing bulk quantities across regions. Many buyers review detailed guidance to align technical decisions with logistics reality.

When these pieces are evaluated together, the decision usually becomes clearer.

Where do disposable CO2 cartridges still make sense?

This is not a one-sided argument.

Disposable cartridges still make sense when volume is low, usage is irregular, or the product lifecycle is short. In these scenarios, simplicity still outweighs long-term efficiency.

Typical examples include:

- Entry-level products

- Trial or pilot markets

- Limited production runs

- Regions with simple disposal rules

Problems arise when brands continue using disposable cartridges after outgrowing these conditions. At that point, convenience gradually turns into friction.

Conclusion

Refillable versus disposable CO2 cartridges is no longer a minor technical detail. For growing brands, it is a structural decision that affects cost control, compliance, and long-term stability.