If you’ve ever inserted a CO2 cartridge into your device—only to find it won’t seal properly, doesn’t screw in, or releases gas too slowly—you’re not alone. Fit issues are one of the most common but overlooked problems in the CO2 cartridge supply chain, especially in B2B use cases like airsoft, soda dispensers, beverage kegs, drain guns, and life-saving gear.

In this article, we explain the key reasons why your cartridge might not be working as expected, how to avoid compatibility issues, and what to look for when sourcing CO2 cartridges for your business.

Why Compatibility Matters (More Than You Think)

Many buyers assume all 12g or 16g CO2 cartridges are the same. But in reality, they can vary in thread type, dimensions, sealing surface, valve construction, gas purity, and intended application. A cartridge that works perfectly in a bike inflator might fail entirely in a soda maker or paintball gun.

For professional buyers—distributors, equipment manufacturers, and OEM brands—a mismatch isn’t just a minor annoyance. It can result in:

- Leakage complaints from customers

- Costly returns and warranty replacements

- Damage to devices due to overpressure or thread stripping

- Safety hazards, especially in compressed gas systems

Understanding compatibility is essential to maintain product quality, safety, and brand trust.

5 Most Common Compatibility Issues

1. Thread Type Incompatibility

The most frequent issue is the wrong thread type. CO2 cartridges come in several threading standards:

- 3/8″-24 UNF (common in air guns)

- 5/8″-18 UNF (used in some beverage systems)

- M10×1 (European standard for soda makers)

Some devices require proprietary threads, especially kitchen-grade or safety-related products.

If the cartridge doesn’t screw in smoothly—stop. Forcing the thread may damage both the cylinder and the device, or worse, cause internal leaks under pressure.

2. Threaded vs. Non-Threaded Types

Threaded cartridges are designed to screw into place, while non-threaded cartridges are punctured using a pressurized chamber or push valve. These two types are not interchangeable unless the device specifically supports both.

Many bike inflators, for instance, are optimized for non-threaded quick-release cartridges. Attempting to use a threaded type can damage the O-ring or fail to trigger release.

3. Size and Volume Mismatches

Even if the thread matches, using the wrong cartridge volume (e.g., inserting a 25g cartridge into a device rated for 12g) can lead to over-pressurization or cause the cartridge to jam without full insertion.

Each CO2 cartridge type is typically manufactured for a specific use case, such as:

- 8g or 12g for handheld soda makers

- 16g for cycling inflators

- 33g or 88g for airsoft rifles

- 24g or 45g for life jackets

4. Sealing Surface and Valve Design

A subtle but important detail is the geometry of the sealing neck. Some cartridges use concave sealing heads, others are flat. The internal valve stem length may also vary, affecting how and when gas is released.

A millimeter difference here can mean slow release, leaking, or no gas at all.

5. Device-Specific Compatibility Constraints

Some high-end or branded devices use exclusive cartridge standards to ensure proprietary sourcing. In these cases, even visually identical cartridges may not function. Always confirm compatibility through testing or documentation before bulk purchasing.

How to Prevent Fit Problems in Bulk Orders

If you’re sourcing CO2 cartridges for resale, OEM application, or as part of an equipment bundle, here are some practical steps to follow:

- Request technical drawings or samples before finalizing orders.

- Match your device specs with our CO2 cartridge specification & shipping guide.

- Clearly define thread types, sealing surfaces, and pressure requirements in your purchase contracts.

- Avoid assuming “one-size-fits-all”—especially if your product is exported to different regions (EU, US, Australia, etc.).

- Verify with your supplier whether cartridges are tested for 100% leak detection and internal cleanliness.

Want a deeper technical overview? The Wikipedia entry on threaded gas connections provides valuable insights into how international valve standards differ across use cases—from beverage to industrial gases.

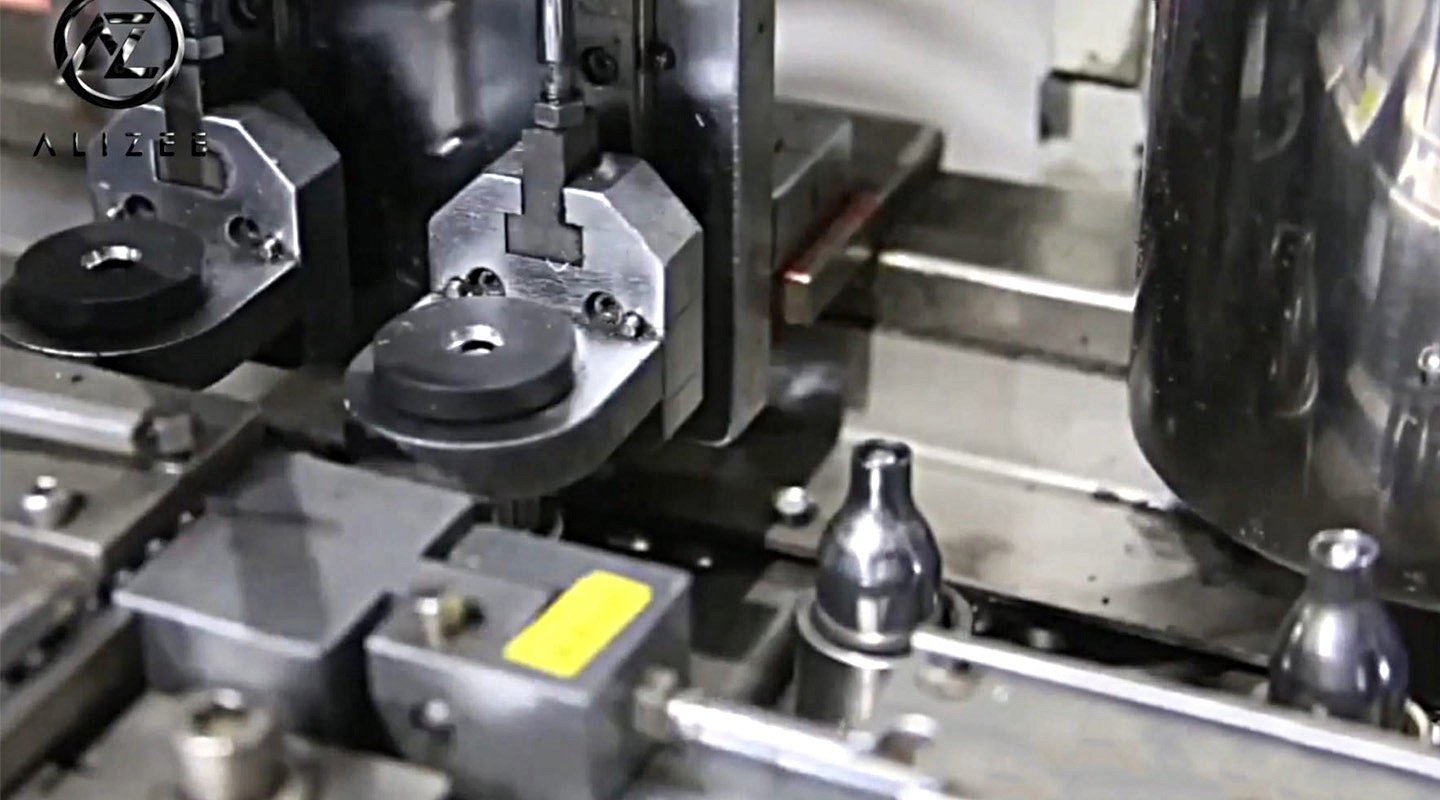

How Alizee Helps You Solve Compatibility Risks

At Alizee Metal, we’ve helped hundreds of global buyers avoid these common pitfalls. Here’s how:

- Custom thread types available for different device categories

- OEM support for compatibility-specific packaging, labeling, and branding

- 100% leak detection and high-pressure testing on every unit

- Full technical consultation before sampling or production

- Low MOQ options for customized formats

We don’t just supply CO2 cartridges—we help our partners build safe, reliable systems their customers can trust.

Final Thoughts: Don’t Let a Millimeter Cost You a Customer

CO2 cartridge compatibility might seem like a small detail, but in reality, it’s a core factor in product performance and user satisfaction. Whether you’re in airsoft, beverage, cycling, or safety products, taking the time to understand thread types, valve designs, and volume specs can prevent technical failures and protect your brand reputation.

Before placing your next order, ask yourself:

Are you 100% sure the cartridge will fit?

If not—now you know what to look for.