Something smells off with your soda system? Your customers might notice it before you do. And no, it’s not your syrup or your machine—it might be your CO2.

Unusual odors from your soda dispenser are often caused by contaminated or industrial-grade CO2 cartridges that aren’t safe for beverage use. Upgrading to certified food-grade CO2 can instantly solve the issue and improve taste, safety, and customer trust.

Over the past 10 years running our CO2 cartridge factory, I’ve seen a lot of cases where clients came to us with one simple problem: “Why does the soda smell bad when everything else is clean?” They clean the nozzles. They swap syrups. Still, the odor stays. That’s when I ask one thing: where are you getting your gas?

Could Non-Food Grade CO2 Be Polluting Your Soda?

One of our clients in Türkiye runs a mid-sized beverage brand. They started getting complaints about a “metallic” and “musty” aftertaste in their soda. At first, they thought it was flavoring gone bad. But when we reviewed their CO2 sourcing, it turned out they were using industrial-grade cartridges bought through a general gas supplier—not food-certified.

Non-food-grade CO2 can contain trace contaminants, oils, or residues not filtered out for consumption. Over time, this can create odd odors, off-tastes, and even health risks.

Switching to 99.99% pure food-grade CO2 cylinders resolved the issue within a week. Taste complaints stopped completely.

More details about soda-compatible cartridges are explained on the Alizeemetal CO2 for soda maker page.

What Makes CO2 “Food-Grade” Anyway?

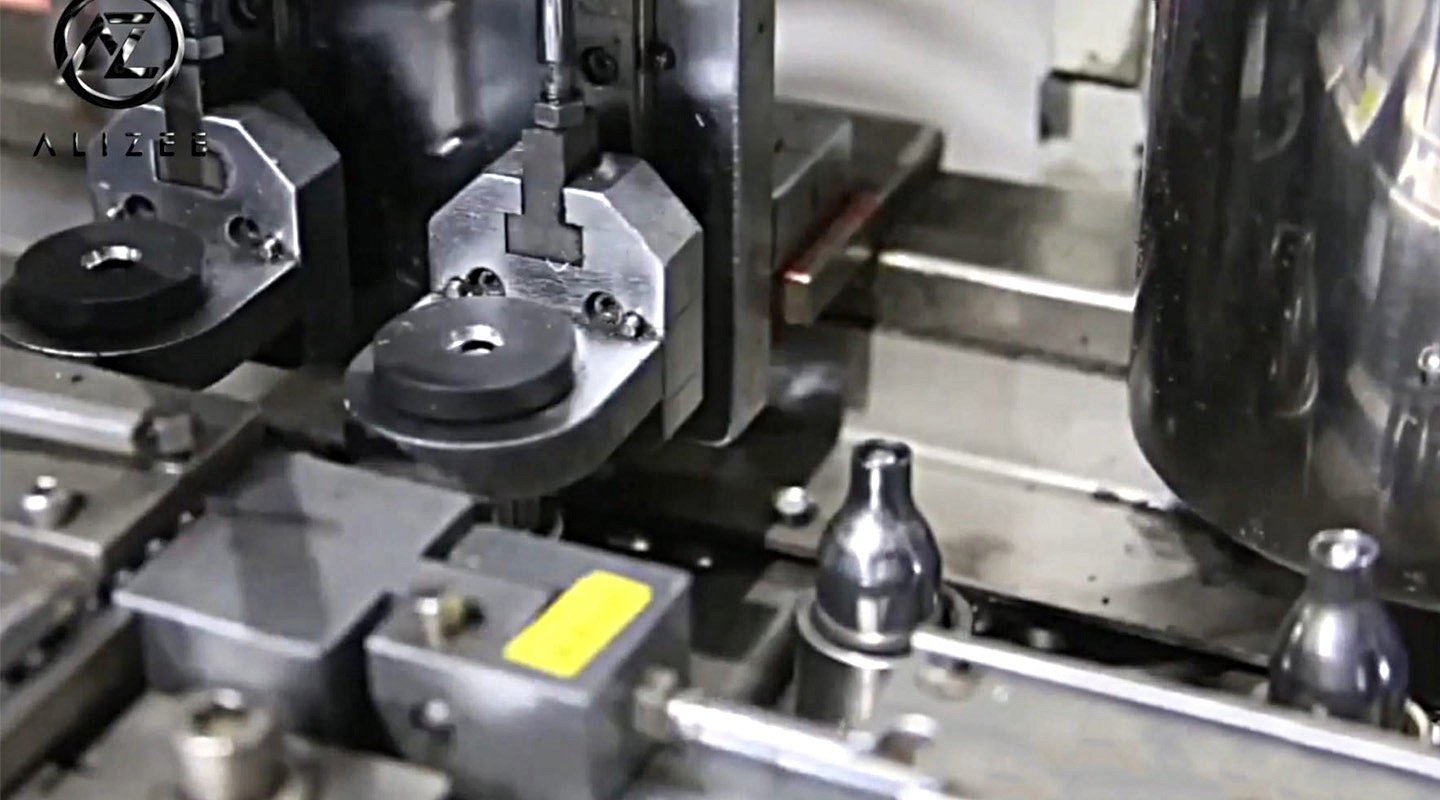

To qualify as food-grade, CO2 must meet strict purification and bottling standards. This includes multi-step filtration, high-pressure leak testing, and cylinder cleanliness standards that align with food production norms. For example, at Alizeemetal, each soda-use cartridge goes through steam cleaning and residue-free drying, especially for export batches.

There are significant differences between food-grade and industrial CO2 in terms of purity levels and allowable contaminants. A breakdown of these differences, particularly how they affect beverage use, is available in the detailed comparison by WestAir Gases.

Are You Using the Right Size and Type of CO2 Cartridge?

Sometimes, even when the CO2 is clean, other problems pop up due to wrong cartridge types. A distributor from Germany once ordered 16g cartridges meant for inflating bike tires for use in their restaurant’s soda dispensers. The result? Inconsistent carbonation, occasional gas leaks, and yes—a faint burnt rubber smell. It was the wrong spec.

For soda makers, standard food-grade CO2 cartridges are usually 8g or 16g, with 3/8 thread, and filled to ~800psi. Always check that you’re matching the specs recommended by your soda machine manufacturer.

| Cartridge Size | Use Case | Thread Type | Food-Grade Available? |

|---|---|---|---|

| 8g | Home soda makers | 3/8 | Yes |

| 12g | Air guns (not suitable) | No thread | Rare |

| 16g | Bikes / Soda | 3/8 | Yes (spec required) |

| 60L Cylinder | SodaStream-style units | Custom | Yes |

Clean Gas, Clean System: The Long-Term Benefits

Using the right CO2 is not just about fixing a smell. It impacts your:

- Customer satisfaction: Soda tastes clean and consistent

- Machine lifespan: No clogging or residue from impure gas

- Compliance: Avoids food safety concerns and potential audits

- Brand image: Customers trust clean, fresh beverages

In fact, one of our Australian partners told us switching to our food-grade cylinders helped them close a new deal with a chain of juice bars. The juice bar’s only requirement? No weird aftertastes in their sparkling fruit sodas.

Conclusion

If your soda smells weird, don’t just clean the nozzle—check your CO2. Your gas source might be telling a story your customers can taste.