For businesses selling or distributing soda makers, nothing frustrates your customers more than a flat drink. When the fizz is gone, the blame often falls on the CO2 cartridge — and in many cases, rightly so.

If your sparkling water system isn’t working properly, chances are it’s due to one of a few common, yet avoidable, issues with your CO2 supply. In this article, we’ll walk through the top three problems people face when using CO2 cylinders with soda machines, and how to solve them effectively.

1. The CO2 Cartridge Doesn’t Fit the Machine

Problem: The cartridge doesn’t screw in or fails to lock into place.

Cause: CO2 cylinders come with different thread types. The most common is 3/8″-24 UNF, but many soda makers — especially proprietary or consumer-focused brands — use unique threads or valve dimensions.

Solution:

- Always double-check the machine’s thread requirement before purchasing in bulk.

- For brands or OEMs, request thread drawings from your cartridge supplier to avoid mismatch.

- Adapter fittings can help in some cases, but are not a long-term solution for large-scale buyers.

To avoid these fitment issues, many commercial buyers prefer sourcing CO2 cartridges specifically designed for soda makers — those that match thread dimensions, valve tolerances, and machine compatibility requirements. Understanding how thread types align with soda machine models can save your team time and money in the long run.

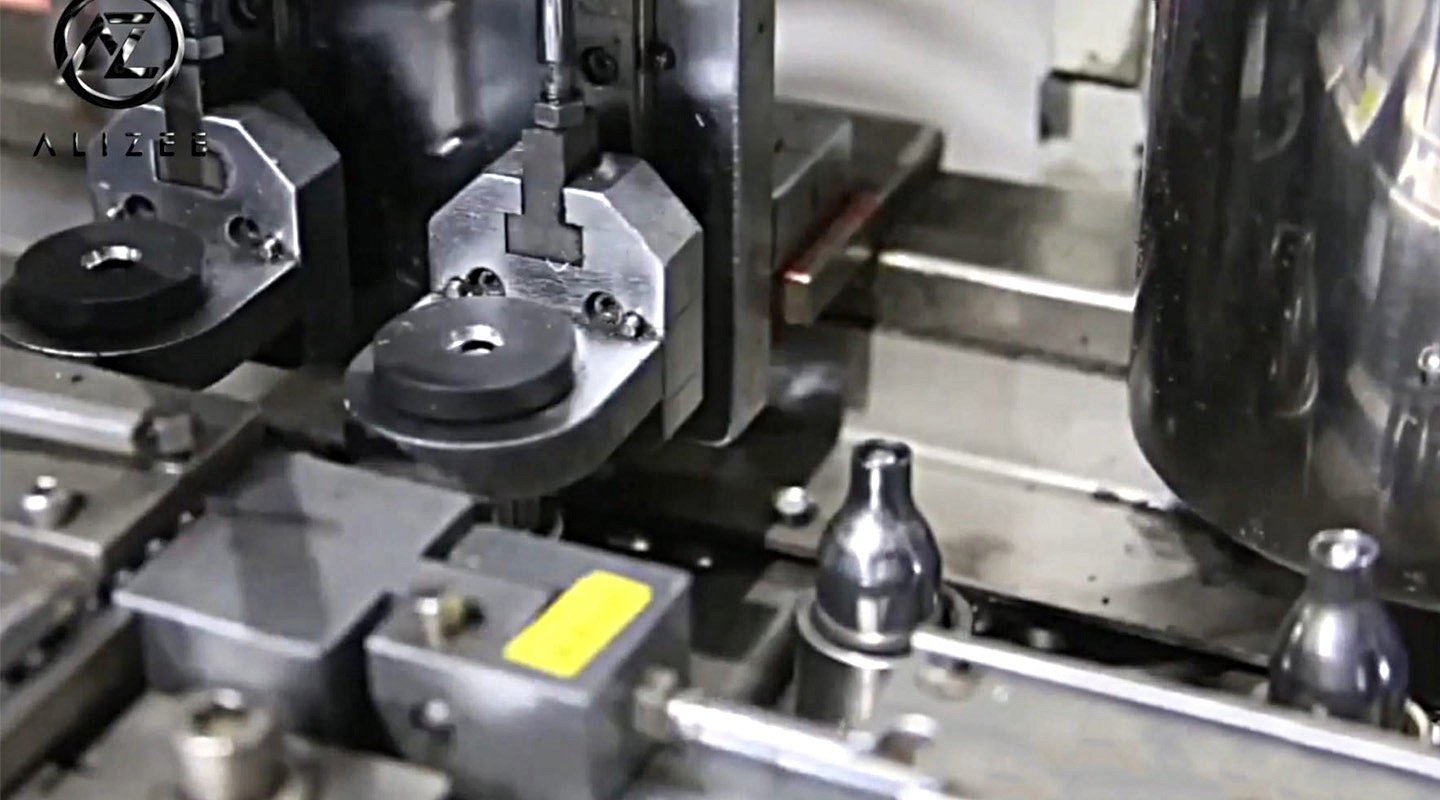

A good example of this alignment can be seen in specialized suppliers like Alizee, who offer cartridges configured for soda dispensing applications based on industry thread norms and OEM needs — see their CO2 cartridge for soda maker configurations for reference.

2. The Gas Doesn’t Dispense Properly

Problem: You hear a faint click, but no gas is released — or only a small amount escapes.

Cause:

- The cartridge may be underfilled or improperly sealed.

- Leakage could be happening at the valve or the connection point.

- Sometimes the piercing mechanism inside the machine doesn’t fully break the seal.

Solution:

- Choose cartridges from manufacturers that conduct leak testing and guarantee gas volume per unit.

- Avoid storing CO2 in extremely cold or hot conditions, which can affect internal pressure.

- Inspect used cartridges — if there’s still gas left after use, the seal may not have been fully pierced.

Most performance failures with CO2 dispensing come down to mechanical misalignment or pressure inconsistency — both of which are governed by strict international standards for cartridge design and testing. If your team handles gas system sourcing or compliance, it’s worth reviewing the cylinder safety and compatibility standards published by the Compressed Gas Association, which outline pressure tolerances, material limits, and leakage thresholds for CO2 cylinders.

3. Inconsistent Carbonation Results

Problem: Sometimes your drinks are fizzy, other times they’re flat — even using the same machine and cartridge size.

Cause:

- Temperature fluctuations affect gas expansion. Cold cartridges yield lower pressure.

- Dirty or aging soda maker valves can partially block gas flow.

- Cartridges from unreliable sources may have inconsistent gas purity or volume.

Solution:

- Store cartridges at room temperature (15–25°C) for stable output.

- Clean soda machines regularly, especially around the piercing valve.

- Use food-grade CO2 with purity above 99.9% to ensure safe, predictable results.

How to Avoid These Problems Altogether

If you’re a distributor, wholesaler, or soda machine brand, you already know that product performance = brand trust.

To minimize product returns and customer complaints, choose a CO2 cartridge supplier who offers:

- ✅ Accurate threading and valve fit

- ✅ Certified food-grade CO2

- ✅ Consistent gas fill weight

- ✅ Leak-proof sealing

- ✅ OEM packaging options

At Alizee, we’ve supplied millions of CO2 cartridges to clients across Europe, the US, the Middle East, and Southeast Asia. Our products are engineered for reliability and customized to meet your market needs — from thread type to private label design.

Final Thoughts

Most soda maker problems are simple — but they cost you money if left unaddressed. Whether you’re sourcing CO2 cartridges for retail, restaurant use, or a soda machine brand, ensuring compatibility and gas quality should be top priority.